Nurturing good people and

creating good products

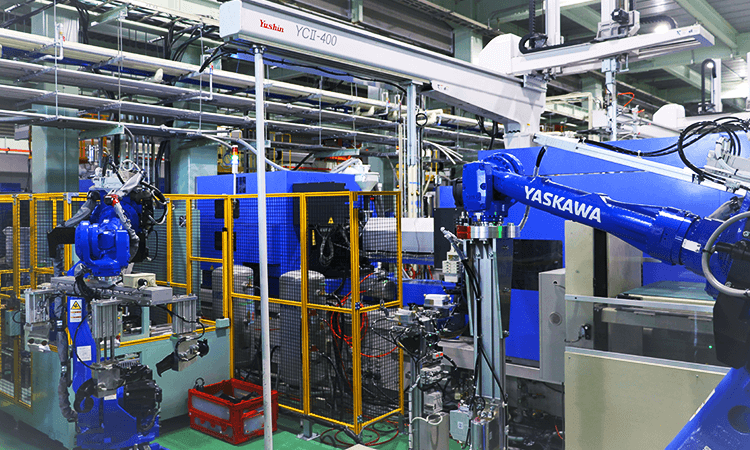

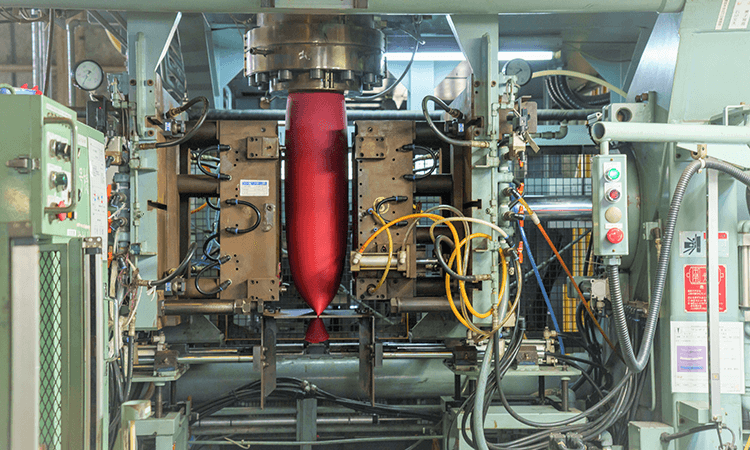

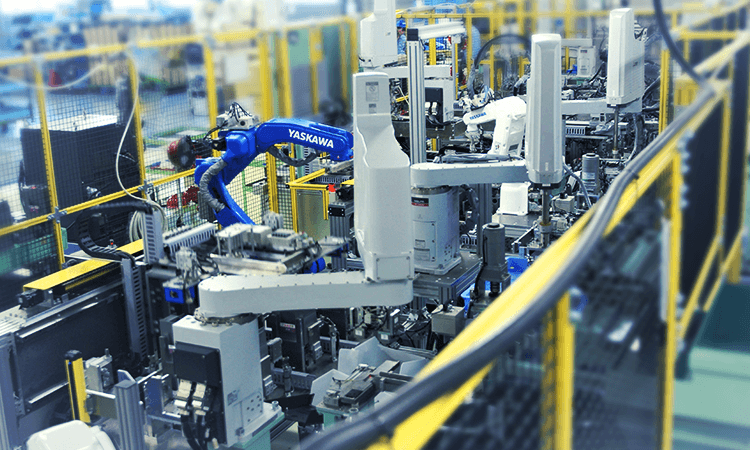

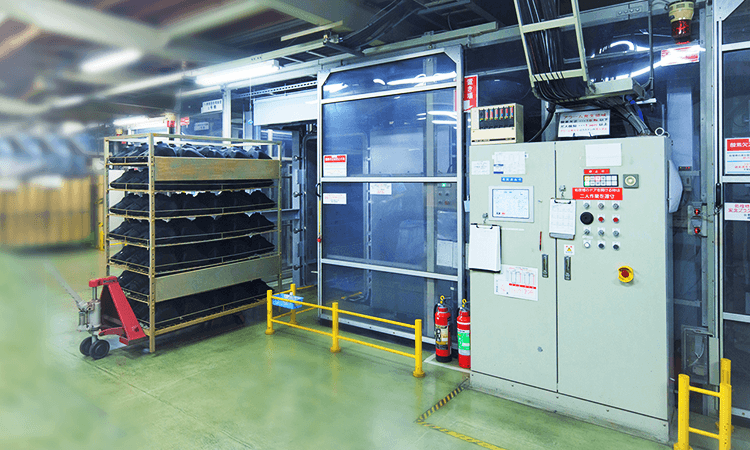

Yazaki is a parts manufacturer

that possesses extensive experience and

superior technology in plastics

and which specializes in blow molding

and injection molding.

-scaled.jpg)

-scaled.jpg)

-1024x682.jpg)