Our Technology & Equipment

ABOUTInjection molding with added value

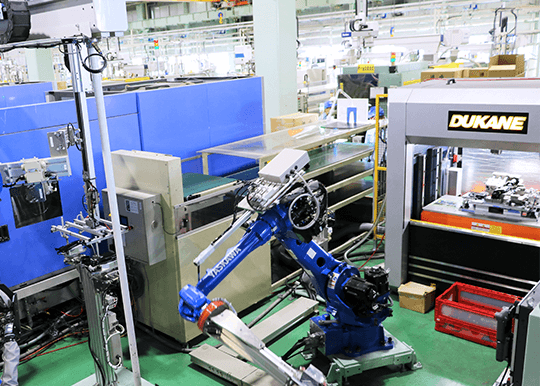

In addition to our wide range of traditional products, we are also responding to the need for lightweight and composite materials required by the shift to electrification in recent years. We are working on increasing value through metal substitution (using various engineering plastics) and integration with welding processes.

Yazaki's Injection Molding

01Optimized molding technology and mold maintenance.

By pursuing the optimum molding conditions based on our experience, and by preserving and managing our molds through effective maintenance, we are able to provide products that balance quality and cost.

02Extensive line-up of molding machines

We have a lineup of horizontal molding machines ranging from 15 tons to 1,000 tons, as well as vertical molding machines of 70 tons and 220 tons, enabling us to flexibly respond to a wide range of demands.

03Supporting a wide range of raw materials

We support a wide range of raw materials to meet the diverse needs of our customers. In recent years, in response to the growing environmental awareness worldwide, we have been actively challenging ourselves to produce recycled and biomass raw materials.

Raw Materials Used

ABS、AES、FRPP、PA11、PA46、PA6、PA66、PBT、PC、PE、POM、PP、PPS、PPSU、PS、PSU、etc...

Injection Molding Product Examples

Outboard motor parts

Injection Molding

Welding

Outboard motor silencer cover

Outboard motor parts

Injection Molding

Welding

Outboard motor oil strainer

Outboard motor parts

Injection Molding

Outboard motor bracket

Motorcycle parts

Injection Molding

Motorcycle thermostat cover

Other

Injection Molding

Bearing retainers

-1024x682.jpg)

OA parts

Injection Molding

Welding

Multifunction machine toner cartridge

Owned Equipment

| Equipment Name | Injection Molding Machine |

|---|---|

| Manufacturer/Model/Capacity, etc. | Horizontal Type: 15t ~ 1,000t Vertical Type: 70t, 220t |

| Number of Machines | 55 |