Our Technology & Equipment

ABOUTQuality control capabilities built from half a century of experience

We have been manufacturing fuel tanks for more than half a century, ever since we were the first in Japan to successfully blow mold fuel tanks from resin, and we have absolute confidence in our quality management. With our unique technology, we have responded to increasingly strict environmental regulations (fuel permeation regulations).

Yazaki's Blow Molding

01Multilayer Molding (4 material, 6 layer molding)

Multilayer blow molding enables the production of resin fuel tanks that meet the US fuel permeation regulations (EPA/CARB). The tank is composed of 6 layers made from 4 different materials, with an EVOH (barrier layer) at the center to prevent the penetration of harmful substances.

02Bright Blow Molding Method

This method provides a glossy surface appearance beyond conventional blow molding and is used for parts that require designability.

03Technology that protects human lives and safety

The smallest defect in a fuel tank can lead to a major accident. We provide safe and reliable products with a thorough quality assurance process that never overlooks even the smallest change.

Injection Molding Product Examples

-1024x682.jpg)

Fuel tanks

Blow molding (single-layer)

Outboard motor fuel tank (portable)

Fuel tanks

Blow molding (multi-layer)

Snowmobile fuel tank

Fuel tanks

Blow molding (multi-layer)

Golf car fuel tank

Fuel tanks

Blow molding (single-layer)

Generator fuel tank

Fuel tanks

Blow molding (single-layer)

Motorcycle fuel tank

-1024x682.jpg)

Fuel tanks

Blow molding (single-layer)

Motorcycle fuel tank

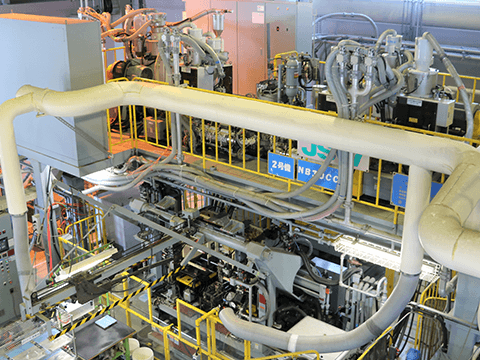

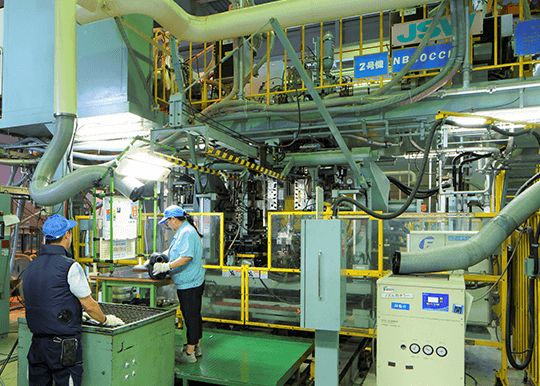

Owned Equipment

| Equipment Name | Blow Molding Machine |

|---|---|

| Manufacturer/Model/Capacity, etc. | Single Layer: 65mm ~ 90mm Multilayer: 30t |

| Number of Machines | Single Layer Machines: 8 Multilayer Machines: 1 |